Hongyi Plastic Round arc seals series Tube 30-40ml/1.00-1.35fl.0z The tail end is smooth and curved, with no sharp corners. It has an elegant and refined appearance, feels comfortable to the touch, and has almost no dead spots when squeezed to the end, resulting in high product utilization.

Recommended applications: High-end essence products, eye care products, local care products, sleep masks, cream sunscreen and so on.

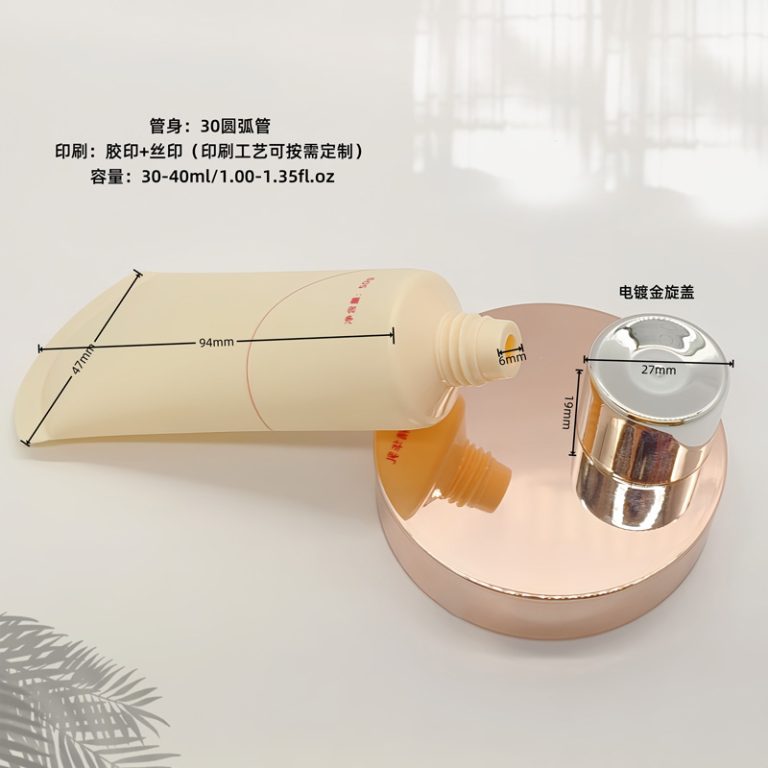

Tube Diameter: 30mm

Filling Capacity: 30-40ml/1.00-1.35fl.0z

Tube Material: PE

Tubing process: Color matte + screen printing 1 color(printing process can be customized as needed)

Cap Material: PP

Cap Decoration:UV electroplating spin cap

Lead Time: 20 Working Days

Pre-production sample time: 10 Days

Minimum Order: 10000PCS

Payment Terms: TT

Feature: Customization

Sample: in Stock

Diameter 30mm: This is a medium to slightly fine-gauge tube, making it easy to control the amount taken out at a time, and the product’s size is suitable for export.

For the pipe’s material quality, we’ve implemented full plastic construction. The pipe surface treatment features a light beige finish. This model adopts a high-tooth design for the injection head, compatible with various high-tooth electroplated screw caps, PP caps, and acrylic screw caps. The printed surface employs matte glossy oil coating, while text and pattern printing utilizes red screen printing technology. The tactile texture enhances user experience through improved tactile feedback.

This tube’s diameter is perfectly suited for your essence or eye cream product, allowing consumers to precisely dispense each time they use it, ensuring that no precious ingredient is wasted.

The curved end design features smooth lines and a comfortable feel, significantly enhancing the product’s grip and visual appeal, making it perfect for brands targeting the mid to high-end market.

Excellent sealing properties provide better protection for the contents, reducing oxidation and contamination. This is particularly suitable for formulations containing active ingredients or those with high requirements for preservation systems.

Product brand advantages

Essence-type products typically have high concentrations of active ingredients and are expensive per unit. Consumers need precise control over the amount used (1-2 grains of soybean-sized each time). The 30-gauge diameter outlet is well-suited to meet this requirement and prevents waste. The refined feel of the rounded, sealed end also aligns with the high-end positioning of essence products.

2.Eye care products

Eye cream, eye essence, eye mask gel.

The eye area is fragile, and only a very small amount is needed (only the size of a grain of rice per use). The fine tube diameter effectively prevents taking too much, ensuring hygiene and cost control. The rounded design has a soft feel and aligns with the gentle nature of eye care products.

Phase 1: Inquiry and communication Initial contact

①Receive inquiry and assign business manager to contact

②We have preliminarily understood the requirements of the inquiry

Details communication of the round arc seals series Tube

①Tube capacity:How many milliliters do you need to fill?

②Tube Size: Diameter of tube

③Length of tube: the length of hose is determined according to the capacity and diameter of the tube.

④Tail closure shape confirmation.

⑤Product content determination: For instance, whether it contain components like oils, acids, or alcohols? Are they corrosive or permeable? Determining the pH level also plays a role in selecting hose materials. These factors collectively determine whether a barrier layer is required during production.

⑥ Target market and regulatory confirmation:

Where is the product sold? Is it in compliance with local regulations? Do you need to provide proof of compliance with materials.

⑦Confirm the color of the tube body

For example, do you need to customize colored tubes or transparent tubes or white tubes? Do you need to have pearlescent effects and so on? Confirm the light oil: glossy, frosted, soft gloss oil.

⑧Printing process determined:

If offset printing is required, how many colors are required and which part of the text and pattern is required?

If screen printing is needed, which part of the text and pattern is required for screen printing?

If you need hot stamping, which part of the text and pattern is required for hot stamping?

If labeling is required, what are the quality requirements for the target paper? What are the better ones? What are the general ones?

Or the above processes can be combined together, specifying which part is what process.

⑨Sealing method

Sealing tail: This hose is characterized by an irregular tail design. Generally, this hose is selected as the default tail seal. The sealing tail usually has straight texture, irregular shape, arc, diagonal texture, etc. Locking cap opening tail: Confirm whether the bottle mouth needs to be attached with aluminum foi.

⑩Determination of hose with cover:Do you need a screw cap or flip cap? Is positioning required? Determine the size, type, color, and manufacturing process of the cap. Stopper for hose bottle mouth: This design does not require a stopper for the hose bottle mouth.

⑪Determine packaging method

⑫Determine the delivery channel: sea, air or other?

2.Depending on whether the confirmed hose tooth profile and tail seal design require additional development of custom molds, the cartoon-shaped tail seal design series in this chain is for new mold development.

3.According to the above plan, a detailed quotation will be provided including: mold opening fee, sample fee, product unit price and transportation fee.

Phase 2: Design and sample production

After business follow-up confirms the intention of cooperation, it enters the stage of turning requirements into physical objects.

Brand pays the mold cost we design and develop the mold according to the confirmed size of the pipe and tail design this step usually takes 20-30 days.

1 Design manuscript confirmation

Sample confirmation The brand needs to strictly review the sample and sign back the sample book after confirmation. We will use this document as the acceptance standard for the subsequent production of large goods.

Phase 3: Mass Production (Production & Quality Control) Production: Upon receiving the official order and deposit from the brand, we procure raw materials and initiate mass production. During manufacturing, quality inspectors conduct random sampling to ensure consistent quality standards across all processes. Full Inspection: After production completion, inspectors perform comprehensive quality checks on finished products and issue a quality inspection report.

Phase 4: Shipping & Delivery Packaging: Products are packaged according to specifications and labeled with shipping marks. Brand Payment: Upon receipt of the final payment, we arrange logistics transportation according to the contract delivery schedule. Phase 5: After-sales Service We address customer feedback and resolve potential service-related issues.

Contact Us For Your Customized Brand!

©2025 Zhejiang Hongyi Plastic Industry Co., Ltd.